Article

What is a Quality Management System? – A Clear Explanation

-

Johannes Eriksson

-

- Quality Management System

- 4 min reading

A quality management system is a strategic tool for leading and developing an organization. It serves as a framework that connects the company’s processes and functions toward shared objectives in order to build a sustainable and competitive organization. When all parts work together, the business can continuously improve by reducing waste, deviations, and costs.

The Purpose of the System

The purpose of a quality management system is to create structure, clarity, and a proactive way of working. It makes it easier for management to follow up on goals, direction, and processes, while providing employees with clear frameworks for their daily work.

The quality management system describes how you:

-

Plan and carry out work

-

Follow up on results and deviations

-

Ensure continuous improvement

-

Deliver quality to customers

Examples of Quality Management Systems

Many organizations build their systems based on international ISO standards to meet customer requirements and strengthen their credibility in the market, for example:

Quality management system (ISO 9001)

Environmental management system (ISO 14001)

Occupational health and safety management system (ISO 45001)

Information security management system (ISO 27001)

How Does It Work?

The system translates the company’s overall objectives into concrete daily work routines. The core principle of most modern systems (including ISO standards) is based on the PDCA improvement cycle (Plan-Do-Check-Act):

The work begins with planning—setting clear objectives and establishing processes for what needs to be done. You then move on to execution, carrying out tasks in line with your defined routines. Once the activities are completed, it is time to follow up and measure results to evaluate whether the efforts achieved the desired effect. If the outcome did not meet the objective, or if a deviation occurred, you must act promptly and correct deficiencies in the next cycle.

What Are the Effects of a Well-Functioning Quality Management System?

A system that is used properly quickly creates positive ripple effects throughout the organization.

For the Business

Structure delivers results on the bottom line. The organization becomes less vulnerable when you work in a standardized and consistent way, as variations and deviations in production or delivery decrease. Active environmental scanning and systematic risk management enable you to anticipate risks or threats and adapt to new legal requirements or market changes in time. The result is a more profitable, efficient, and predictable business where continuous improvement is part of the culture.

For Employees

An inclusive quality management system builds confidence and trust at the individual level. It helps employees understand their exact responsibilities and the important role they play in the bigger picture. Clear instructions gathered in one place allow new hires to get up to speed quickly and feel part of the team. When the system encourages participation, engagement grows and employees feel confident driving development forward themselves.

Building a Solid Foundation

Establishing a quality management system requires a structured approach and is built on several interconnected components that translate an unclear strategy into everyday practice.

1. Vision and Mission

Everything starts with where you are heading and why the organization exists. This forms the overarching compass for all activities and sets the tone for company culture. A strong quality management system is built on a clear direction, where each employee understands the higher purpose of their daily work. When the vision is well anchored, it becomes easier to motivate change and build engagement across the organization

2. Stakeholder Requirements

You need to understand expectations from customers, suppliers, owners, internal functions, and regulators to build a relevant structure. A quality management system that does not consider stakeholder requirements risks losing its purpose. Carefully map out who is affected by your operations and what they expect in terms of product quality, delivery precision, and working conditions. This deep understanding creates a stable platform for prioritizing the right processes and building long-term sustainable relationships.

3. Environmental Analysis

Monitor technological advancements, new sustainability requirements, and competitor developments to adapt your operations and stay ahead. Markets evolve rapidly, and your quality management system must be flexible enough to meet new challenges. A structured analysis of trends and regulatory changes provides the right basis for making timely strategic decisions, reducing vulnerability, and capturing new business opportunities before others do.

4. Risk Management

Analyze potential risks within the organization and create action plans to manage them before they cause harm or production disruptions. Identify weak links in workflows, assess consequences, and implement proactive routines that protect both employees and profitability. Documented measures enable you to act quickly and methodically if something unexpected occurs.

5. Objectives and Strategies

Set SMART objectives (Specific, Measurable, Accepted, Realistic, Time-bound) based on your vision, requirements, and expectations. These objectives should then be broken down and linked to daily operations. Clear goals create alignment from top management to each individual employee. With a structured quality management system, it becomes easy to follow up, celebrate successes, adjust direction when necessary, and keep the entire organization motivated along the way.

Important Considerations When Choosing a Quality Management System

All critical information should be gathered in one place. A cloud-based quality management system gives employees direct access to updated routines around the clock, wherever they are. When evaluating different digital solutions, consider the following:

User-Friendly for Everyone

The system must be easy to understand and use for all employees. If the threshold for reporting a deviation or finding a specific routine is too high, engagement will decline. An intuitive and logical interface saves time every day and encourages participation in improvement efforts.

Flexibility and Relevance

Choose a solution that can be tailored to your specific processes, objectives, standards, and certifications. The platform should adapt to your needs to create real value and meet specific customer and regulatory requirements.

Scalability for the Future

A quality management system must be able to grow at the same pace as the company and adapt as needed. Market conditions continuously change through new legal requirements, organizational restructuring, and emerging business opportunities.

Onboarding and Support

A supplier that offers personal guidance often makes all the difference during implementation. The right support and well-planned training from the start ensure a faster launch and help you build a logical structure from day one.

Create Structure and Value with AM System

With AM System Classic, you get a dynamic and integrated quality management system that makes it easy to involve the entire organization. The platform gathers everything in one place and helps you build a structure that lasts over time.

Here’s how AM System Classic creates value for you:

-

All in one place: Replace scattered documents and binders with a centralized solution for all processes and cases.

-

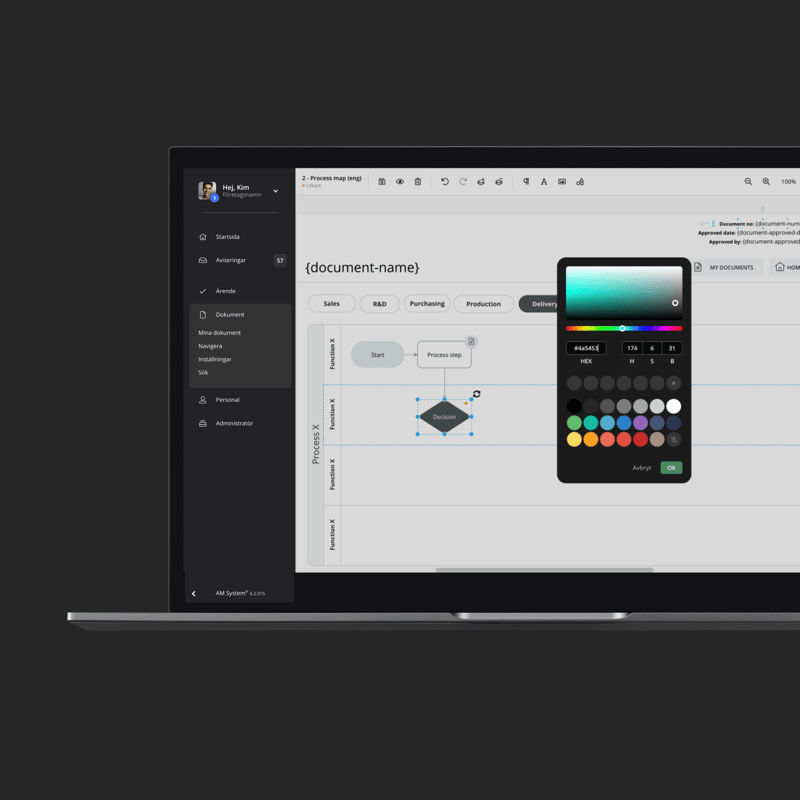

Visual process maps: Create clickable workflows that give employees a crystal-clear understanding of how work connects.

-

Living documentation: Policies and procedures are always available in their latest version with built-in traceability.

-

Efficient case management: Establish clear workflows to assign responsibilities and ensure tasks are completed on time.

-

Tailored experience: Build inviting, user-friendly homepages customized for different roles.

-

Improved collaboration: Engage colleagues directly within the platform and drive progress together as a team.

-

Global reach: Support for Swedish, English, and additional languages simplifies communication for international operations.

-

Full accessibility: The web-based, mobile-adapted solution works equally well in the office and on the production floor.

-

Maximum security: The platform is ISO 27001 certified, offers detailed access control, and maintains 99.98% uptime.

-

Personal onboarding: Receive personal guidance and training from day one to get started quickly and build correctly from the start.

Get a demo

Ready to make work easier - and more enjoyable?

Want to see for yourself how AM System can make a difference for you? Book a demo and discover how easy it is to create structure, efficiency, and seamless workflows in your daily operations.