Article

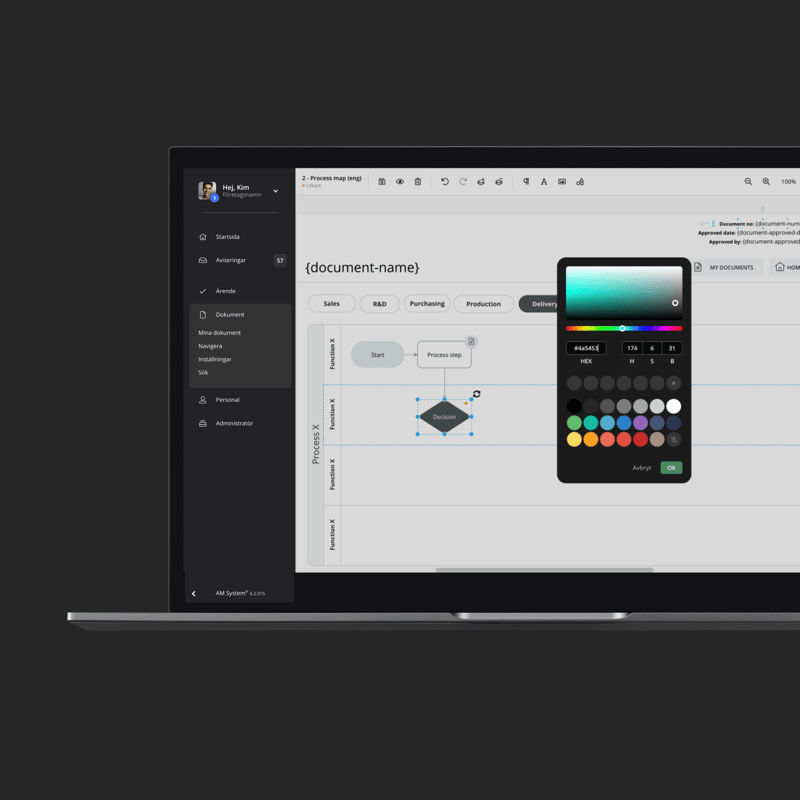

Digital traceability with AM System

-

Editorial team

Editorial team

-

- Case Management

- 2 min reading

Traceability - A strategic advantage for your business

Traceability can be a legal requirement, a quality standard or simply a way to gain better control and optimize your business. With AM Systems' cloud-based case management, you can create a traceability system that gives you full visibility of the entire flow - from delivery to end customer. The system allows you to track products, processes and materials in real time and ensures that you can act quickly in the event of any deviations.

Build a digital traceability system in AM System

AM System's case management allows you to create a customized traceability system where you define the data to be recorded. With customizable forms and automatic logs, you can easily follow every step of the process and see who did what and when.

- Automatic traceability - The system records all changes in real time and creates a complete history.

- Cloud-based access - Work seamlessly from your desktop, mobile or tablet, wherever you are.

- Efficient search and filtering - Quickly find the right information based on supplier, product or date.

Integrate traceability across your business

By linking traceability to your business processes, you ensure that all relevant information is collected and managed smoothly.

- Supplier tracking - Document and track deliveries to ensure quality and compliance.

- Production control - Track raw materials, batch numbers and production processes in detail.

- Customer and complaint management - Get full visibility of where products have been delivered and manage complaints effectively.

Food traceability: Internal and external tracking

The food industry has strict traceability requirements, both internally and externally. With AM System, you can ensure that you have full control over where food comes from, how it is handled internally and where it is sent.

- Internal traceability - Identify ingredients, handling and processes to reduce the risks and costs of recalls.

- External traceability - Ensure you can account for exactly where products come from and where they are delivered.

- Automated reports - Collect and export data during inspections and compliance checks.

Efficient management of traceability data

Collecting and storing the right information is crucial to meet regulatory requirements and ensure quality operations. With AM System, you can store and manage all relevant data digitally, making it easily searchable and accessible when needed.

- Supplier and customer register - Collect all necessary information about business partners.

- Digital storage of delivery notes and receipts - Ensure that important information is always available.

- Automatic retention periods - Customize how long data is stored based on product shelf life and industry requirements.

Production traceability - Improve quality and safety

Many manufacturing industries use traceability systems to identify problems, improve quality control and manage complaints. By digitizing traceability in AM System, you can proactively identify risks and quickly take action.

- Identify and analyze production deviations - See trends and take action in time.

- Automatic documentation of material flows - Get a complete picture of how raw materials and components are used.

- Full transparency for the entire organization - Give both operational staff and management visibility into data and decision-making.

With AM Systems Case Management, you can create a traceability system that not only meets legal requirements and standards, but also contributes to a more efficient, safe and profitable business.

Get a demo

Ready to make work easier - and more enjoyable?

Want to see for yourself how AM System can make a difference for you? Book a demo and discover how easy it is to create structure, efficiency, and seamless workflows in your daily operations.