Article

FMEA - Failure Mode and Effects Analysis

-

Editorial team

Editorial team

-

- Quality Management System

- 5 min reading

What is FMEA?

FMEA, or Failure Mode and Effects Analysis, is a structured method for identifying and preventing potential failures in processes, products or systems. It is used to analyze risks before they lead to problems and is particularly used in quality assurance, process and product development and improvement work. AM System Classic helps organizations to work proactively with FMEA analysis, create robust processes and conditions for constantly addressing the highest risks in the business.

Purpose

The purpose of FMEA is to identify where and how errors can occur, assess the consequences they have and prioritize actions based on risk level. By analyzing failure modes at an early stage, businesses can reduce risks, ensure quality and strengthen customer satisfaction. The method is required and particularly used in the manufacturing industry and sectors such as mobility, energy, aerospace, defense and medical technology.

Types of failure modes and impacts

The methodology can be applied at different levels depending on what is to be analyzed - from overall systems and design to specific processes and products. By breaking down the analysis into different categories, it is easier to identify risks where they actually occur and to prioritize the right actions at the right stage of the work.

Systems

Systems FMEA is used to analyze risks at an overall level, where several subsystems or functions interact. The analysis focuses on how failures in one subsystem can affect other parts of the system or the functioning of the whole product. FMEA is often used early in the development process to ensure robust architecture and minimize complexity-related risks.

Typical areas of focus are:

- Interactions between mechanical, electrical or software-based components

- Failures in interfaces between systems and subsystems

- Functional safety risks (e.g. according to ISO 26262 or IEC 61508)

- Consequences of control system failure or system breakdown

Process

FMEA is often used to analyze manufacturing processes or workflows. It identifies errors that may occur during production, assembly or service delivery - for example, mishandling, machine stoppages, lack of instructions or variations in execution. The aim is to improve process stability and eliminate sources of error.

Typical areas of focus are:

- Improper handling or manual variation in work steps

- Machine breakdowns or process stops that affect delivery reliability

- Material deviations or incorrect input data to the process

Why FMEA?

FMEA as a risk analysis provides structure and transparency in risk management. It helps organizations make data-driven decisions, prioritize resources and work systematically on improvements. It strengthens collaboration between departments, as it often involves cross-functional teams. FMEA is also an important part of ISO 9001 and IATF 16949 quality management systems.

A good support in risk management and quality assurance

FMEA is most powerful when it is part of an intuitive process, accessible and facilitates maintenance and continuous risk management. Existing knowledge, complemented by effective non-conformance work, where previous FMEA assessments are analyzed, creates a learning process and continuous improvement.

- Proactive control: Minimize or eliminate errors early in your product and process development. Risk prioritization guides planning, staffing and investments.

- Seamless traceability: Every action can be followed from identified risk to effect in production.

- Audit-ready quality: Updated FMEAs facilitate ISO/IATF audits and customer audits.

How FMEA works - step by step

Effective FMEA analysis requires a structured approach where each step builds on the previous one. It follows a clear work process that ensures risks are identified, analyzed and managed in a systematic way. Below are the eight main steps of an FMEA analysis:

1. delineate the analysis

Define the purpose, scope and system boundaries. Identify which products, subsystems or process steps are included and which are excluded.

- Output: clear scope description, responsibilities, schedule.

2. describe functions and flows

Map out how the product will work or how the process actually works. Feel free to use a flowchart or VSM.

- Output: function list, process map, critical interfaces.

3. identify failure modes

List possible ways the function or step could fail based on your own unique expertise and experience with the process.

- Examples: "leakage", "incorrect assembly", "insufficient curing", "data missing".

4. Causes and effects

Use standardized assessment matrices or those obtained via customer-specific requirements.

- Output: cause-effect chains that facilitate root cause analysis.

5. assess and prioritize risks (RPN)

Once all potential failure modes have been identified, their risk level should be assessed and prioritized. This is done by analyzing severity, probability and detectability. These are used to calculate a Risk Priority Number (RPN) or similar, which gives an indication of which risks should be addressed first.

- Severity (S): How serious is the impact if the failure occurs?

- Likelihood (L): How likely is it that the failure will occur?

- Detectability (D): How likely is it that the error will be detected before it reaches the customer or the next step in the process?

The RPN is calculated according to the formula:

RPN = S × O × D

Example: If a failure mode has been assessed with S = 9 (high impact), O = 6 (moderate occurrence) and D = 5 (difficult to detect), the RPN is 9 × 6 × 5 = 270. This indicates a high level of risk that requires immediate action to reduce the likelihood or increase the detectability.

6. plan actions

Select actions that reduce O or D in the most cost-effective way. Set the responsible person, deadline and expected outcome based on prevention, detection or risk reduction measures.

- Examples: design change, Poka-Yoke, SPC, enhanced testing.

7. implement and verify

Implement measures, verify effectiveness and update assessments. Ensure that processes and instructions reflect the change.

- Output: updated FMEA, traceable change history.

8. monitor and improve

Monitor key performance indicators, capture deviations and feed back lessons learned. FMEA is a living document, not a one-off exercise.

- FMEA can be linked to the work of your internal audits and your deviation management.

Challenges

Despite its benefits, an FMEA analysis can be time-consuming and complex - especially if not used properly. Common challenges include a lack of structure, insufficient documentation or the analysis becoming a one-off exercise rather than part of a continuous improvement effort. Digital tools such as AM System Classic can streamline the work and ensure follow-up over time.

Key principles

Effective FMEA is based on cross-functional collaboration and fact-based decisions. Let teams from development, quality, production and purchasing contribute their perspectives.

- Cross-functional collaboration

- Fact-based assessments

- Focus on preventive actions

- Continuous monitoring

- Documentation and traceability

- Customer focus and safety awareness

7 benefits of FMEA

A well-conducted FMEA reduces costs, improves quality and contributes to the long-term stability of your business. Here are some of the key benefits:

1. prevents failures before they occur

By analyzing potential failure modes during the planning and development phase, risks can be eliminated before they affect operations. This saves time and resources compared to dealing with problems afterwards.

2. increases reliability and product quality

FMEA contributes to stable processes and consistent results by focusing on root causes. The result is fewer interruptions, fewer quality deviations and higher delivery reliability.

3. reduces costs associated with errors and complaints

Fewer errors in production and at the customer's premises means reduced quality defect costs, rejects, rework and warranty claims. This leads to lower operating costs and reduced waste of resources over time.

4. facilitates certifications and audits

FMEA supports the requirements of ISO 9001, IATF 16949 and other quality standards. The methodology provides clear documentation of risk management and improvement efforts, facilitating both internal and external audits.

5. Creating safer processes and products

Focusing on safety and risk control reduces the likelihood of serious non-conformities. The result is a safer working environment and products that deliver on their promises.

6. boosts competitiveness

Companies that take a proactive approach to risk can deliver higher quality in less time. This increases customer satisfaction and improves the ability to win new business in competitive markets.

7. increases customer confidence

When risks are managed professionally and proactively, it builds trust with customers, partners and stakeholders. With FMEA, you can both prevent problems and build long-term relationships by delivering consistent results every time.

Tips to succeed with your FMEA analysis

Start early, keep the analysis up to date and integrate it into regular quality work.

- Start early in the project

- Use a standardized FMEA template for comparability over time.

- Involve the right competencies.

- Link to data (field failures, test results, OEE) for more accurate assessments.

- Prioritize actions with highest risk value.

- Link to action systems to ensure that responsibilities and status are always clear.

- Revise when there is a change in design, supplier or process technology.

- Follow up and improve the process continuously.

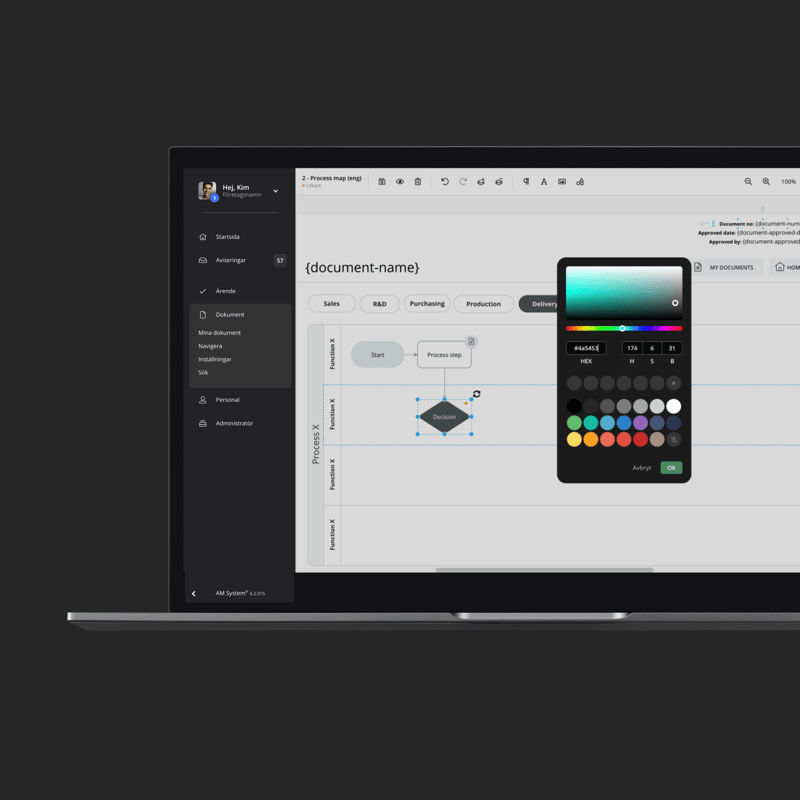

FMEA in AM System Classic

With the FMEA module in AM System Classic, the analysis work becomes easier, more structured and traceable. The system gathers all information in a clear overview and makes it easy to prioritize actions, create responsibilities and follow up results. With AM System Classic, the FMEA analysis becomes a natural part of the organization's improvement work, where you get a quick overview and traceability that can be used in deviation management. You get a uniform method, automated prioritization and real-time status on each risk and its possible actions.

Features of AM System Classic

- Customizable FMEA template

- Automated risk prioritization (RPZ)

- Action log with responsibilities and deadlines

- Visualization of risk levels

- Real-time analysis

- Ability to collaborate on ongoing FMEA projects

- Version management and audit trail

- Good overview to simplify work with deviations

- Reports for documentation, follow-up and audit

Get a demo

Ready to make work easier - and more enjoyable?

Want to see for yourself how AM System can make a difference for you? Book a demo and discover how easy it is to create structure, efficiency, and seamless workflows in your daily operations.