Article

5S checklist of actions for better workflow

-

Editorial team

Editorial team

-

- Quality Management System

- 2 min reading

A 5S checklist is a practical tool to help you work in a structured and orderly way. It helps you ensure that the same checks are made every time, regardless of workplace or team, and makes follow-up and improvements easier over time - especially when 5S becomes part of your quality management system. The 5S method is used in various industries but mainly in the manufacturing industry and is an important pillar in improvement methods such as Six Sigma and Kaizen as well as quality philosophies such as TQM (total quality).

AM Systems complete 5S checklist with tips

Below is a practical 5S checklist that can be used in any type of business - from the shop floor to the office. Each step contains checkpoints with recommended activities for systematic improvement.

1. sort - remove what is not needed

Purpose: Free up space, reduce clutter and make workspaces easier to work on.

- Remove tools and materials that are not used regularly

- Label items that need to be moved, sold or disposed of

- Identify safety hazards in the form of clutter or disorder

- Establish criteria for what to keep and what to get rid of

Tip: Use a "Red Tag" procedure for clarity and quick overview.

2. Systematize - give everything a specific place

Purpose: Ensure quick access, create workflow and minimize searching.

- Decide where each tool or product should be stored

- Label shelves, cabinets, drawers and floor surfaces

- Place frequently used items in easy reach

- Use visual aids such as color coding or tool board with markings

Tip: Document the layout as a standard - preferably visually.

3. Clean - keep the workspace clean and safe

Purpose: Create a predictable and safe work environment and facilitate the detection of deviations.

- Develop daily or weekly cleaning routines

- Ensure that machines, tools and work surfaces are cleaned regularly

- Identify sources of dirt and leaks

- Address the cause of problems - not just the symptoms

Tip: Document cleaning procedures as checklists or digital cases in a case management system.

4. standardize - make the order sustainable

Purpose: Ensure that the 5S methodology becomes a habit and not a one-off project.

- Define roles and responsibilities for each area

- Create visual standards and instructions

- Implement procedures through training

- Introduce regular audits

Tip: Use structured problem-solving methods to prevent recurrence and reinforce standards.

5. Create habits - maintain discipline

Purpose: Ensure that work continues over time and constantly evolves.

- Conduct 5S round or audit weekly/monthly

- Measure progress with scoring system or photo documentation

- Follow up on deviations and organizational barriers

- Introduce improvement ideas via Kaizen or improvement boards

Tip: Involve teams in evaluating the areas - it increases ownership and quality.

Digital support for sustainable 5S work

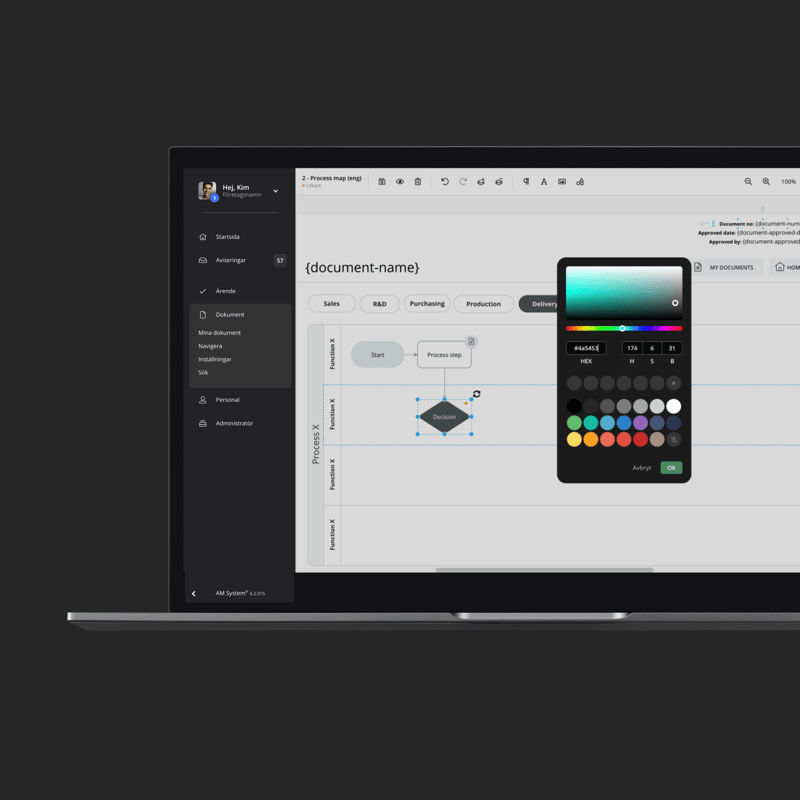

Combining a 5S checklist with digital support makes it even easier to follow up and improve. Working with 5S in AM System Classic helps you gather controls, documentation and drive actions and follow-up in one place, making 5S work more sustainable over time.

Get a demo

Ready to make work easier - and more enjoyable?

Want to see for yourself how AM System can make a difference for you? Book a demo and discover how easy it is to create structure, efficiency, and seamless workflows in your daily operations.