Article

Lean – What is it? A deep dive into the Lean method

-

Editorial team

Editorial team

-

- Quality Management System

- 2 min reading

What is Lean?

Lean is a methodology that focuses on creating more value for the customer with fewer resources. By identifying and eliminating waste, organizations can streamline processes, improve quality and create a culture of continuous improvement. With AM System, you can digitize and structure your Lean work, providing clear flows, measurable results and a sustainable way to drive efficiency and growth.

The goal of the method

The goal of Lean as a method is to focus on what really creates value, while removing unnecessary steps and inefficient routines. The method is used in everything from manufacturing and production - known as Lean Production - to service companies and public sector operations.

Principles

To understand what Lean is, you need to look at the basic principles behind the model. These are universal and can be applied in small and large organizations in a variety of industries.

1. Value for the customer

All work should be based on what creates value for the customer. Understanding the customer's needs and delivering products or services that best meet them is the top priority.

2. identify waste

Lean is about minimizing activities that do not add value and addresses 8 types of waste. These can be overproduction, waiting times, unnecessary transportation or duplication of work.

3. flow and efficiency

Processes should flow smoothly and seamlessly without interruptions or bottlenecks. This makes it easier to deliver the right quality at the right time.

4. continuous improvement

A core of Lean is to always strive for development and improvement in processes, production and work culture. The 5S method is an effective tool for organizing operations in the long term.

5. commitment and participation

To succeed with Lean, all employees need to be engaged and feel responsible for the results. Participation leads to greater motivation and better results.

Benefits of Lean

There are many short- and long-term benefits to working according to the Lean methodology:

- More efficient processes: Removing unnecessary steps saves both time and resources.

- Higher quality: A clear focus on customer value and standardized ways of working reduces errors and deviations.

- Increased flexibility: Lean makes it easier to adapt to changing needs and requirements.

- Better working environment: A structured methodology helps reduce stress and clarify roles.

- Increased competitiveness: Efficiency and quality lead to more satisfied customers and a stronger market position.

Lean at work

Lean can be applied in all types of businesses, regardless of industry. By systematizing and digitizing your processes, you get better control and a more sustainable work structure. Lean work encompasses both daily operational work and strategic improvement initiatives. Examples include implementing digital systems for case management and process mapping, or using the 8D method to ensure quality and customer satisfaction by managing deviations and finding root causes of problems.

The difference between Lean and analog processes

Traditionally, many processes have been analog and dependent on manual work and physical documents. With Lean, it is natural that work becomes more digitized and data-driven, for example with a document management system. By working according to the method, your organization gains:

- Faster decision-making through a clear overview.

- Reduced risk of mistakes and loss of information

- More effective cross-departmental collaboration.

4 ways to succeed with Lean

Lean success requires a clear strategy and long-term commitment.

- Embed Lean principles with management and throughout the organization.

- Create measurable goals and continuously monitor results.

- Encourage employee participation and engagement.

- Ensure that the right digital tools are in place to support the work.

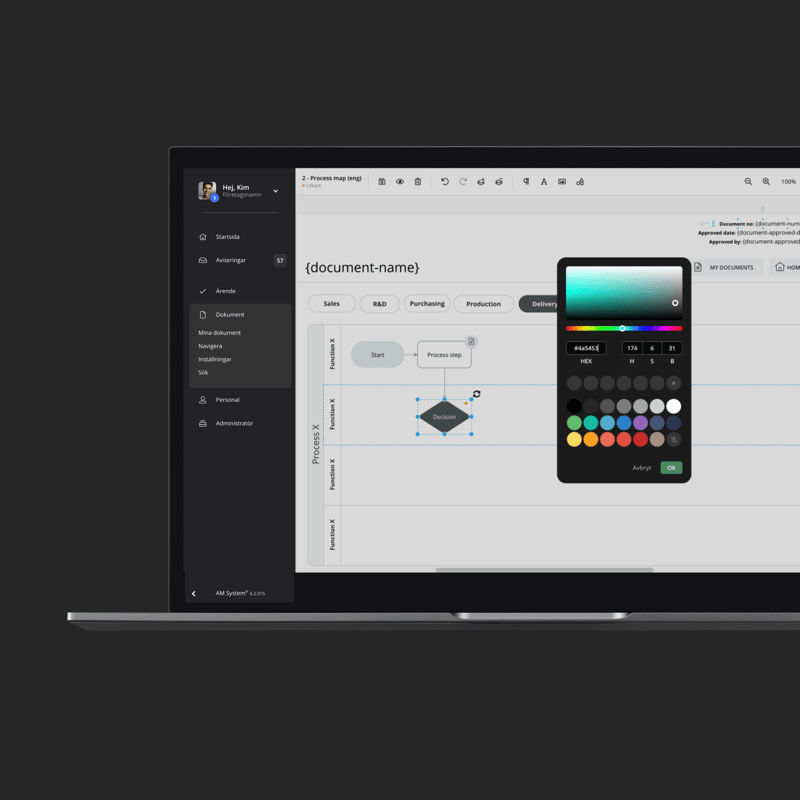

Lean with AM System

With AM System, you can digitize your Lean processes and gain full control over quality work, deviation management and improvement initiatives. Our digital management system makes it easy to visualize flows, document results and follow up on goals. A structured digital approach makes it easier to achieve the goals of the Lean model - high quality, efficient processes and continuous improvement.

Get a demo

Ready to make work easier - and more enjoyable?

Want to see for yourself how AM System can make a difference for you? Book a demo and discover how easy it is to create structure, efficiency, and seamless workflows in your daily operations.